No products in the cart.

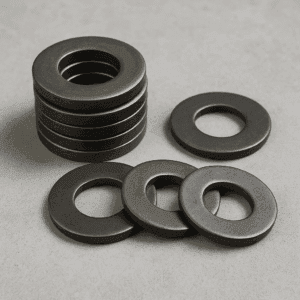

Heavy Duty Spring Washers – Built to Withstand Industrial Tension and Vibration

In high-pressure industrial settings where joints are constantly exposed to stress, motion, or vibration, using standard flat washers simply won’t do the job. That’s where heavy duty spring washers come in — engineered to absorb shock, maintain tension, and deliver long-term fastening reliability.

Whether you operate in the construction, mining, or heavy machinery industry, having the best heavy duty spring washers for construction equipment can make all the difference in ensuring structural integrity and safety.

What Are Heavy Duty Spring Washers?

Heavy duty spring washers are a type of lock washer designed with a conical or split-ring shape to provide axial flexibility. When compressed between a nut and a bolted joint, they exert a continuous force that prevents the assembly from loosening due to vibration or dynamic loads.

They are particularly favored in environments where bolts or screws face:

High torque tension

Constant movement

Mechanical shock

Temperature fluctuations

Applications of Heavy Duty Spring Washers

Spring washers aren’t just small components — they’re essential industrial fasteners in large-scale operations. Their resilience is invaluable across many sectors:

Common Industries:

Construction machinery and cranes

Railways and transportation systems

Wind energy and turbines

Earthmoving equipment

Oil & gas pipelines

Heavy electrical and transformers

From holding a hydraulic cylinder in place to preventing bolt loosening in engine assemblies, high tension lock washers for vibration control are a critical component.

How They Work – The Science Behind the Spring

Unlike flat washers that merely distribute load, spring washers act as a mechanical spring. When tightened, the washer flattens under load and stores potential energy. This energy pushes back against the nut or bolt, maintaining tension and keeping the joint tightly secured.The result? Fewer maintenance checks, longer service life, and less chance of equipment failure due to loose fasteners.

Types of Heavy Duty Spring Washers We Offer

At Nafees Metal Industries, we manufacture and supply a wide variety of spring washers suitable for all industrial needs.

| Type | Application |

|---|---|

| Split Lock Washers | General-purpose vibration control |

| Belleville Spring Washers | High load, low deflection |

| Conical Spring Washers | Excellent for thermal expansion zones |

| Heavy-Duty Toothed Washers | Ideal for secure electrical contact |

| Wave Washers | Ideal for small deflection ranges |

We also offer customization based on material strength, coating, and inner/outer diameter.

Key Technical Specs

| Property | Specification |

|---|---|

| Material | Carbon Steel, Stainless Steel, Spring Steel |

| Surface Finish | Blackodised, Zinc Plated, Phosphated |

| Size Range | M3 to M72 (and custom) |

| Standards | IS 3063, DIN 127, DIN 2093 |

| Testing | Load deflection, hardness, fatigue resistance |

All washers are manufactured under strict quality control and conform to industry benchmarks for safety and performance.

Why Choose Nafees Metal Industries?

With decades of experience in the manufacturing of industrial fasteners, we understand the nuances of heavy-duty applications and engineer washers that deliver high performance in every setting.

Highlights:

In-house tool design for precise stamping

Heat treatment for consistent spring action

Rust-resistant finishes

Ready inventory for fast dispatch

Custom orders with dimensional accuracy

We work with OEMs, equipment manufacturers, and infrastructure contractors to provide bulk orders of heavy duty spring washers with consistent quality and competitive pricing.

Bulk Supply and Custom Manufacturing

We accept bulk inquiries from industries that require large-scale usage of spring washers, especially in high-load environments.Whether you need a thousand pieces or ten thousand units of high tension lock washers for vibration control, we’ve got you covered.

Custom Orders Include:

Specific load-bearing capacities

Uncommon diameters and thicknesses

Application-based coating or treatment

Laser engraving for OEM identification

Pro Tips for Choosing the Best Heavy Duty Spring Washers

- Choose the Right Material – Use stainless steel for corrosion-prone areas and carbon steel for standard equipment.

- Assess Load Requirements – For very high loads, Belleville or conical types are ideal.

- Go for Treated Washers – Anti-rust coatings extend service life in outdoor or marine environments.

- Buy from Reliable Manufacturers – Avoid poor-quality imports. Look for tested and standardized options.

When it comes to fastening reliability in demanding conditions, there’s no substitute for heavy duty spring washers. They don’t just hold things together—they protect your operations from costly breakdowns and safety hazards.

At Nafees Metal Industries, we’re committed to delivering the best heavy duty spring washers for construction equipment and industrial machines across the country and beyond. Get in touch with us to explore how our washers can keep your equipment secure and efficient.

Tags: best spring washers for heavy loads, construction equipment fasteners, heavy duty spring washers, industrial fasteners, lock washers, Nafees Metal Industries, spring washers manufacturer, vibration control washers

Related posts

Introduction When it comes to assembling heavy-duty structures, every small detail matters. One of the most crucial yet often overlooked components is the thick flat... Continue reading

Introduction When it comes to withstanding extreme loads and maintaining structural integrity, not all washers are created equal. High strength washers are engineered for the... Continue reading

When it comes to demanding industrial or structural applications, the smallest components often play the biggest roles. One such unsung hero in the world of... Continue reading

In the realm of industrial fasteners, one component silently shoulders immense responsibility — the heavy-duty flat washer. These simple yet powerful circular discs are crucial... Continue reading

Heavy duty washers are used in engineering, construction, and heavy machinery, every component must be designed to withstand extreme stress. These washers are built not... Continue reading

Leave a reply