No products in the cart.

High Strength Washers – Essential Support for Structural Fastening

Introduction

When it comes to withstanding extreme loads and maintaining structural integrity, not all washers are created equal. High strength washers are engineered for the most demanding applications — particularly in construction, infrastructure, heavy machinery, and other high-torque environments. These rugged components may seem simple, but they play a pivotal role in distributing loads and protecting bolts and surfaces under immense pressure.

In this blog, we explore why high strength washers are the go-to solution for engineers, project managers, and industries that cannot afford structural failure.

What Are High Strength Washers?

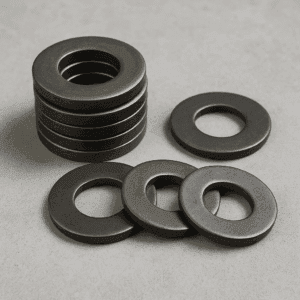

High strength washers are typically made from materials like high carbon steel or alloy steel and are heat-treated to enhance their load-bearing capacity. Their design and material composition allow them to withstand extreme tensile forces, prevent bolt loosening, and increase the lifespan of fastened joints.

They are often paired with high tensile bolts to ensure uniform performance across the fastening system. Common finishes include black oxide, zinc-plating, and hot-dip galvanization, which offer corrosion resistance for various environmental conditions.

Applications of High Strength Washers

Construction and Infrastructure: In bridges, skyscrapers, and industrial buildings, high strength washers ensure bolts stay tight under dynamic stress and load-bearing activity.

Heavy Machinery and Equipment: High torque environments like bulldozers, cranes, and turbines require washers that can absorb vibrations and shocks without deforming.

Railways and Transport Infrastructure: Fastening tracks and Structural Fasteners with high tensile bolts and washers ensures long-lasting safety and minimal maintenance.

Oil & Gas and Energy Sector: Environments that face intense pressure changes, extreme temperatures, or chemical exposure benefit greatly from durable washer solutions.

Why Choose High Strength Washers Over Standard Washers?

✅ Durability in High-Stress Conditions:

Unlike standard washers that may deform under pressure, high strength washers retain their shape and performance integrity.

✅ Load Distribution:

They evenly spread out the load from the bolt head or nut, reducing the chance of surface damage or warping.

✅ Enhanced Safety:

They reduce the risk of bolt loosening or joint failure – especially important in structural and safety-critical applications.

✅ Long-Term Cost Savings:

Fewer failures and replacements mean reduced downtime and maintenance costs

How to Select the Right High Strength Washer?

At Nafees Metal Industries, we specialize in manufacturing and supplying premium-grade high strength washers. Whether you’re looking to buy high strength washers online, Industrial Hardware or require custom sizes for your project, our robust production capabilities and quality assurance practices make us your trusted partner.

We serve construction firms, OEMs, industrial suppliers, and infrastructure projects across India and abroad.

Where to Buy the Best High Strength Washers?

At Nafees Metal Industries, we specialize in manufacturing and supplying premium-grade high strength washers. Whether you’re looking to buy high strength washers online or require custom sizes for your project, our robust production capabilities and quality assurance practices make us your trusted partner for best high strength washers for construction.

We serve construction firms, OEMs, industrial suppliers, and infrastructure projects across India and abroad.

Conclusion

In high-performance and high-risk environments, using subpar fasteners is never an option. High strength washers provide the added assurance, safety, and longevity required by today’s engineering demands. As infrastructure and technology continue to evolve, these humble yet essential components remain at the heart of structural reliability.

Tags: best washers for construction, buy washers online, heavy duty washers, high strength washers, industrial hardware, structural fasteners

Related posts

Introduction When it comes to assembling heavy-duty structures, every small detail matters. One of the most crucial yet often overlooked components is the thick flat... Continue reading

When it comes to demanding industrial or structural applications, the smallest components often play the biggest roles. One such unsung hero in the world of... Continue reading

In the realm of industrial fasteners, one component silently shoulders immense responsibility — the heavy-duty flat washer. These simple yet powerful circular discs are crucial... Continue reading

In high-pressure industrial settings where joints are constantly exposed to stress, motion, or vibration, using standard flat washers simply won’t do the job. That’s where... Continue reading

Heavy duty washers are used in engineering, construction, and heavy machinery, every component must be designed to withstand extreme stress. These washers are built not... Continue reading

Leave a reply