No products in the cart.

Understanding High-Tensile Washers – Strength Meets Reliability in Fastening

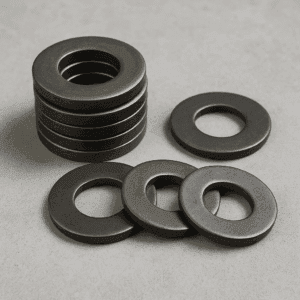

When it comes to demanding industrial or structural applications, the smallest components often play the biggest roles. One such unsung hero in the world of fastening is the high-tensile washer. Known for their exceptional strength, load-bearing capacity, and resistance to deformation, these washers are indispensable in numerous engineering, construction, and manufacturing applications.

What Are High-Tensile Washers?

High-tensile washers are flat, circular metal components used with bolts and screws to distribute load and reduce wear. What makes them distinct from standard washers is their material strength—typically made from hardened steel or alloy, treated with heat processes to achieve high tensile strength ratings.

Tensile strength refers to the washer’s ability to withstand tension (pulling or stretching forces) without breaking. This is a critical feature in heavy-duty environments where fasteners are subject to extreme stress or vibration.

Why Choose High-Tensile Washers?

1. Enhanced Durability Under Load

Unlike standard washers, high-tensile variants resist deformation under high stress. This makes them ideal for structural applications such as steel frame construction, bridges, and heavy machinery.

2. Better Load Distribution

They ensure even load distribution around the bolt or screw head, preventing localized stress and potential material failure.

3. Corrosion Resistance Options

Many high-tensile washers are coated or made from stainless materials for enhanced performance in corrosive environments, extending their service life.

4. Supports High-Torque Applications

Their strength allows them to withstand higher torque, which is essential in automotive, aerospace, and power transmission sectors.

Applications Across Industries

🏗️ Construction and Infrastructure

In construction, where structures are exposed to heavy loads and dynamic forces, using the best high-tensile washers for construction ensures joint integrity and safety.

🚜 Automotive and Agricultural Machinery

Vehicles and machinery that experience constant movement and vibration benefit greatly from high-tensile washers that prevent loosening over time.

🛠️ Manufacturing and Industrial Equipment

In environments where fasteners must endure frequent loading/unloading cycles, high-tensile washers maintain performance consistency.

🛒 Why Buy Bulk High-Tensile Washers Online?

With the rising demand in industries and growing e-commerce platforms, businesses can now buy bulk high-tensile washers online at competitive prices. Whether for large-scale projects or for maintaining stock, bulk purchases reduce unit costs and simplify procurement.

At Nafees Metal Industries, we offer a wide range of high-tensile washers tailored to industry-specific needs. Our washers are precision-manufactured and go through stringent quality checks to ensure consistent strength and performance.

Material Grades and Standards

Most high-tensile washers conform to international standards such as:

ISO 898-1 for mechanical properties

DIN 125 / DIN 7989 for shape and tolerance

IS 6649 for Indian heavy-duty applications

Popular material grades include:

EN8 / EN19

Grade 8.8, 10.9, and 12.9

Stainless steel 304 / 316 for corrosion resistance

How to Identify Genuine High-Tensile Washers

To ensure you’re getting the highest quality washers:

Check for markings and grade stamps

Review mill test certificates

Ensure dimensional accuracy

Confirm with suppliers about tensile strength and coating specifications

Conclusion

High-tensile washers are much more than just metal rings—they’re the backbone of secure and reliable fastening in high-stress environments. Choosing the right washer enhances the performance of the entire assembly, ensuring safety, durability, and cost-efficiency over time.

Looking to secure your next project with the strongest fastening solutions? Explore Nafees Metal Industries’ collection of industrial washers and heavy-duty fasteners tailored to your needs.

Tags: bulk washer supplier, buy high-tensile washers online, construction hardware, heavy-duty fasteners, high-tensile washers, industrial fasteners

Related posts

Introduction When it comes to assembling heavy-duty structures, every small detail matters. One of the most crucial yet often overlooked components is the thick flat... Continue reading

Introduction When it comes to withstanding extreme loads and maintaining structural integrity, not all washers are created equal. High strength washers are engineered for the... Continue reading

In the realm of industrial fasteners, one component silently shoulders immense responsibility — the heavy-duty flat washer. These simple yet powerful circular discs are crucial... Continue reading

In high-pressure industrial settings where joints are constantly exposed to stress, motion, or vibration, using standard flat washers simply won’t do the job. That’s where... Continue reading

Heavy duty washers are used in engineering, construction, and heavy machinery, every component must be designed to withstand extreme stress. These washers are built not... Continue reading

Leave a reply