No products in the cart.

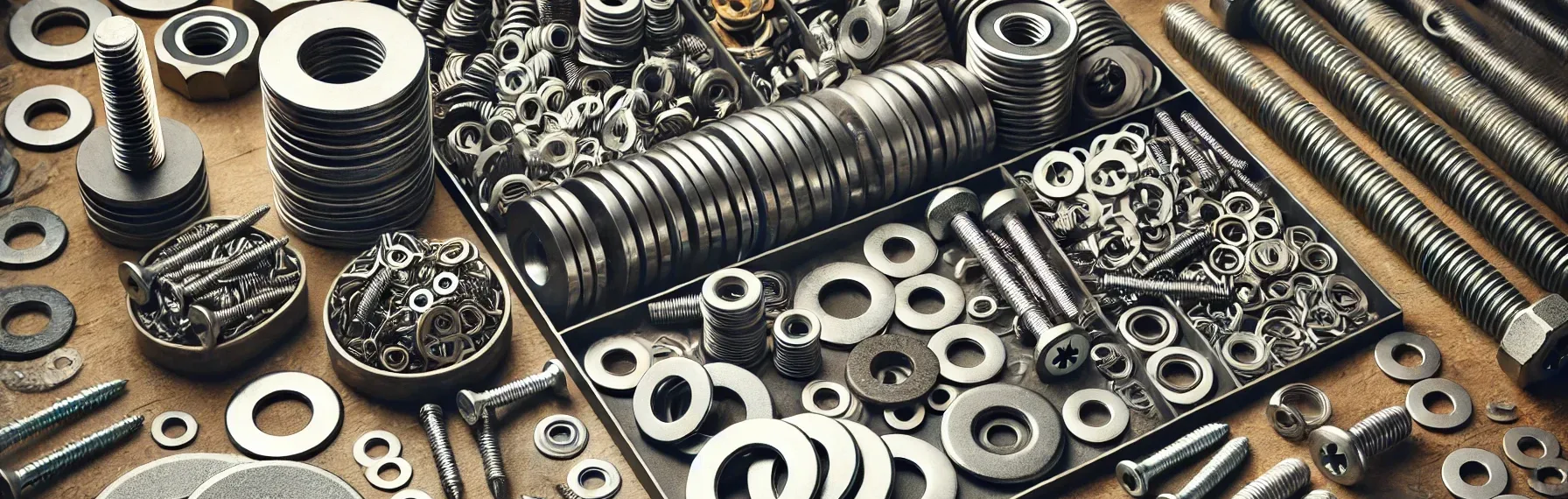

Difference between Plain, Flat, Punched & Machined Washers

What is the difference between plain washers, machined washers and flat washers?

Washers are often used interchangeably, but they have slight differences.

- Plain washers are simple, flat discs used to distribute load and prevent damage to surfaces.

- Flat washers, a subset of plain washers, are specifically designed to evenly distribute load under a bolt or nut, protecting the material underneath.

- Machined Washers can be made from a variety of materials and are typically customized for specific tolerances and applications that require high precision.

M3 Mild Steel Plain Washers

M4 Mild Steel Plain Washers

M5 Mild Steel Plain Washers

M6 Mild Steel Plain Washers

M8 Mild Steel Plain Washers

M10 Mild Steel Plain Washers

How are punched washers manufactured?

Punched washers are manufactured using a power press machine.

- The process involves punching out the washer shape from sheet metal, ensuring precision in size and dimensions.

- This method is cost-effective and ideal for high-volume production, making punched washers widely used in electrical and construction industries.

What are the key applications of Plain washers?

Plain washers are highly precise and used in industries where accuracy and durability are critical.

- They are commonly found in aerospace, automotive, and defense sectors.

- Their customizability ensures they meet specific requirements for high-performance equipment.

Can I order customized washers?

Yes, at Nafees Metal Industries, we offer customization for washers. Click here and share your requirements.

- You can provide specifications such as size, material, and thickness.

- We ensure precision manufacturing tailored to your needs, with adherence to industrial standards.

Why are flat washers important in load distribution?

Flat washers are critical for load distribution because they:

- Prevent damage by evenly spreading the load of a bolt or nut.

- Protect the surface material from deformation.

- Enhance the stability of the fastened joint, ensuring durability and safety.

Why Our Washers Stand Out?

At Nafees Metal Industries, we don’t just produce washers; we provide solutions that ensure durability, performance, and cost-effectiveness for your projects. Here’s why our washers are the preferred choice across various industries:

- Precision Engineering: Our washers are designed to meet the most stringent tolerance requirements. Whether you need high-precision machined washers or durable flat washers, we use advanced technologies to ensure exceptional accuracy in every product.

- Sustainable Manufacturing: We focus on environmentally responsible manufacturing processes. From sourcing raw materials to waste management, we ensure our operations are sustainable and eco-friendly.

- Industry Certification: Our washers adhere to international industry standards, including ISO certifications, ensuring that you receive products that meet rigorous safety and quality benchmarks.

Best Washers Manufacturer in Mumbai | High-Quality Plain, Flat, Punched & Machined Washers

At Nafees Metal Industries, we are recognized as the best washers manufacturer in Mumbai, India providing top-notch washers for a wide range of applications. Whether you need plain washers, flat washers, punched washers, or metal washers, we offer high-quality, durable, and customizable washers that cater to the needs of industries ranging from automotive to aerospace.

We take pride in our precision manufacturing process, delivering washers that meet the highest standards and exceed customer expectations.

Custom Sizes Available: Contact us for custom-sized plain washers designed for your unique requirements.

Related posts

Introduction Fastening heavy equipment, large structures, or critical machinery demands more than just strong bolts or nuts. The often-underestimated heroes behind reliable connections are Large... Continue reading

Introduction When it comes to assembling machinery that must endure high stress and heavy loads, ordinary washers are simply not enough. High strength flat washers... Continue reading

Introduction In the fast-paced world of mechanical engineering and construction, achieving perfect fastening without damaging surfaces or compromising bolt tension is crucial. One tiny yet... Continue reading

In industrial and engineering applications, the importance of a strong fastening solution cannot be overstated. Among the specialized washer types, dome washers stand out as... Continue reading

Washers play an essential role in the fastening industry, especially when it comes to maintaining structural integrity and reducing friction between components. Among the most... Continue reading

One comment on “Difference between Plain, Flat, Punched & Machined Washers”

vorbelutr ioperbir

obviously like your web site however you need to test the spelling on quite a few of your posts. Many of them are rife with spelling issues and I to find it very troublesome to tell the reality on the other hand I will definitely come back again.