No products in the cart.

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Buy Quality Assured products

Worldwide Delivery

Get Customized Washers in bulk quantity

Menu

Categories

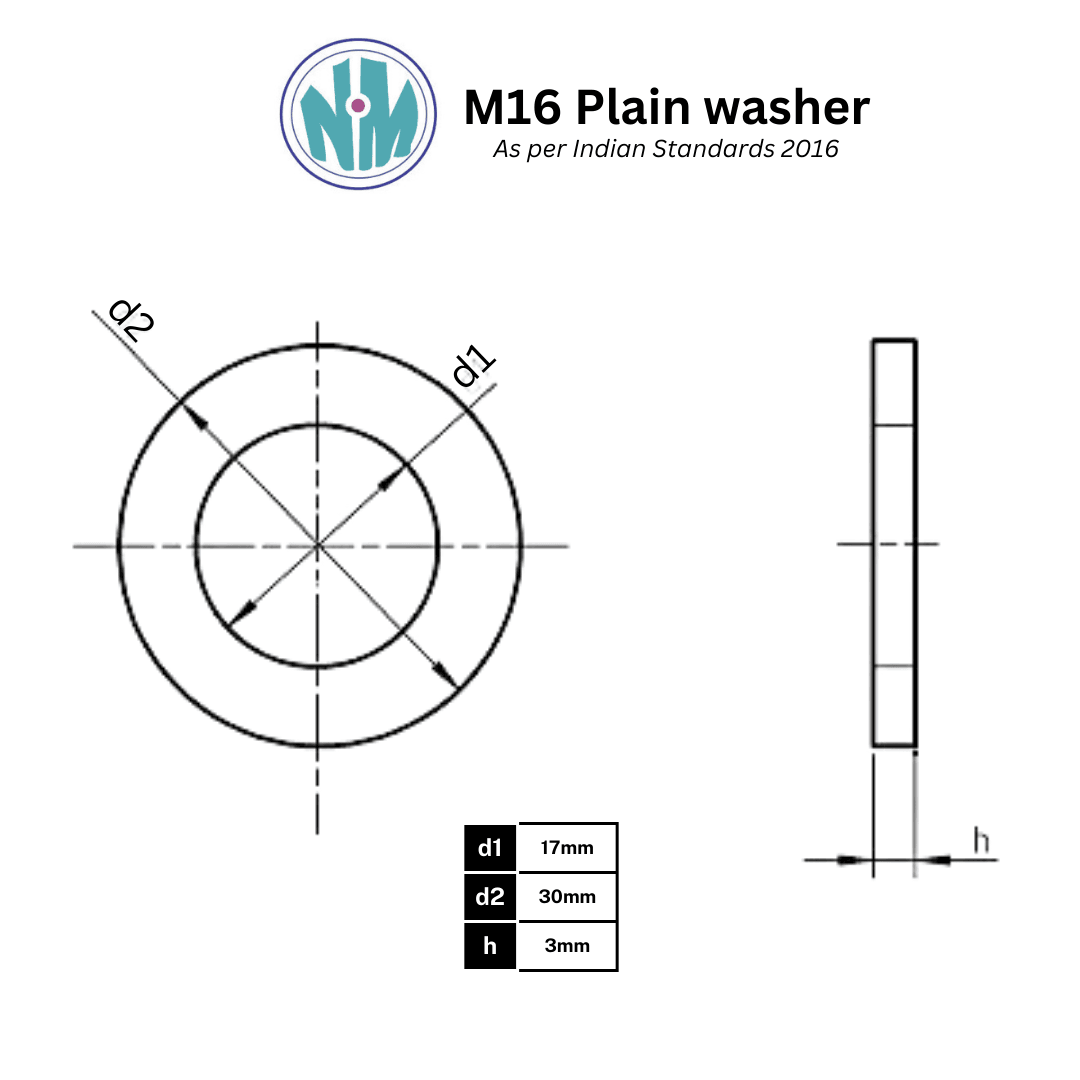

*Images shown for graphic representation. Not to scale.

M16 Mild Steel Plain Washers – Precision-Engineered Strength for Every Industrial Application

Introduction

Washers are often the unsung heroes in industrial applications. Their small size belies the massive impact they have in ensuring the integrity, safety, and longevity of fastened components. In heavy-duty or high-vibration settings, washers play an instrumental role by distributing load, minimizing loosening, and protecting surface finishes.

When selecting a washer, material choice is critical. Each material has a unique behavior under pressure, heat, corrosion, and stress. Mild steel stands out as a cost-effective yet high-performance option, making M16 Mild Steel Plain Washers ideal for a wide range of industrial uses.

At Nafees Metal Industries, we specialize in producing precision-grade M16 Mild Steel Plain Washers tailored to meet industrial standards. With state-of-the-art machinery and rigorous quality control, we’re positioned as your trusted supplier.

Whether you’re seeking durability, affordability, or performance, our M16 Mild Steel Plain Washers deliver uncompromised excellence.

What Are M16 Mild Steel Plain Washers?

M16 Mild Steel Plain Washers are circular, flat components with a central hole that fits M16 bolts and fasteners. Their primary function is to distribute load evenly across the surface, preventing bolt pull-through and protecting the assembly’s integrity.

From a technical standpoint, these washers:

- Spread pressure over a larger area

- Provide resistance against vibration loosening

- Protect surfaces from abrasion

M16 Mild Steel Plain Washers Excel In:

1. Load Distribution

One of the most essential mechanical functions of M16 Mild Steel Plain Washers is their ability to distribute load uniformly. When a bolt or screw is tightened, the pressure exerted can create a concentrated force at the point of contact with the material surface. Over time, this can lead to material fatigue, surface deformation, or even cracking in softer materials.

M16 Mild Steel Plain Washers act as an intermediate layer between the fastener and the material. Their wide bearing surface spreads the load across a larger area, significantly reducing the chances of indentation or localized stress. This feature becomes even more important in applications involving wood, plastic, or composite materials, where surface strength is lower than that of metals.

2. Vibration Resistance

Fasteners in dynamic environments are constantly subjected to vibrations and movement. Without proper dampening, these vibrations can loosen the bolts or nuts over time, resulting in failure of the joint. M16 Mild Steel Plain Washers help minimize this risk.

They serve as cushions that absorb minor shocks and vibrations, reducing micro-movements that can loosen fasteners. While they are not a replacement for locking washers in extremely high-vibration scenarios, M16 Mild Steel Plain Washers still offer an essential first line of defense against joint failure caused by repeated motion. This makes them valuable in automotive, machinery, and structural applications where stability is critical.

3. Surface Protection

Direct contact between the fastener and the material surface can lead to wear and surface damage. Over time, metal-on-metal interaction can cause scratches, dents, and in some environments, accelerated corrosion due to frictional wear or exposure to moisture.

M16 Mild Steel Plain Washers serve as a protective buffer. They isolate the fastener from the material, preserving the finish and preventing galvanic corrosion when different types of metals are used in an assembly. This is particularly beneficial in aesthetic applications or in products exposed to weather elements where long-term corrosion resistance is desired.

4. Long-Term Benefits

Using M16 Mild Steel Plain Washers may seem like a small addition, but it leads to significant long-term performance improvements. Assemblies that include washers tend to have fewer issues with fastener loosening, surface degradation, or mechanical wear.

Over extended periods, this translates to reduced maintenance frequency, lower replacement costs, and enhanced operational safety. Whether the washer is used in a static structure or a moving component, its impact on longevity is tangible. It also ensures that periodic re-tightening of fasteners is minimized, saving time and labor in industrial and commercial setups.

5. Material-Specific Properties of Mild Steel

M16 Mild Steel Plain Washers are manufactured from mild steel—a material known for its excellent balance of strength, ductility, and affordability. Mild steel can be easily cut, punched, or pressed into shape, making it ideal for producing large volumes of washers with consistent precision.

Its mechanical properties are well-suited for medium-load applications where toughness and resistance to deformation are more critical than hardness. Moreover, mild steel can be galvanized or plated for corrosion resistance, further extending the washer’s lifespan in harsh or outdoor environments. Its cost-efficiency makes it an ideal choice for industries aiming to maintain quality without inflating production budgets.

Material Details: Why Mild Steel?

Mild steel (commonly referred to as MS) is a low-carbon steel offering a fine balance between strength, flexibility, and cost-efficiency.

Composition of Mild Steel:

- Carbon: 0.05% – 0.25%

- Iron: Balance

This low carbon content enhances ductility and weldability, making mild steel ideal for plain washers.

Comparison with Other Grades:

- SS304: Higher corrosion resistance but costlier

- SS316: Marine-grade corrosion resistance but not needed for general use

- Mild Steel: Best for indoor or non-corrosive environments at a much lower cost

Advantages:

- Excellent machinability

- Superior weldability

- Cost-effective for large-scale production

- High load-bearing capacity

Mild steel is perfectly suited for M16 Mild Steel Plain Washers, providing a durable and budget-friendly solution.

Manufacturing and Technical Specifications

We employ advanced manufacturing techniques, including:

- Precision stamping using high-tonnage power press machines

- CNC machining for dimensional accuracy

- Heat treatment to enhance durability

- Surface coating (zinc, black oxide) upon request

All washers undergo rigorous quality checks for thickness, diameter, and flatness.

Technical Specifications Table:

| Parameter | Specification |

|---|---|

| Inner Diameter | 17 mm |

| Outer Diameter | 30 mm |

| Thickness | 2 mm |

| Finish | Self-finish / Zinc / Black Oxide |

| Material | Mild Steel |

| Shape | Round (Flat) |

Key Features

- Uniform load distribution

- High-precision fit and finish

- Excellent resistance to vibration

- Surface abrasion and corrosion protection (when coated)

- Compatible with various bolt types

- Designed for structural durability

- Suitable for automated assembly systems

- Customizable in terms of thickness and diameter

Applications of M16 Mild Steel Plain Washers

M16 Mild Steel Plain Washers are highly versatile mechanical components used across a broad range of industries and applications. Their primary function is to distribute the load of a threaded fastener and prevent damage to the joint surface, but their importance goes far beyond basic fastening. Here is an in-depth look at where and how these washers are commonly used:

1. Heavy Machinery and Equipment Manufacturing

M16 washers are a staple in the assembly of heavy-duty machines such as bulldozers, cranes, and earthmovers. In such environments, equipment is exposed to extreme mechanical loads, vibrations, and high torque. The washers help:

Maintain bolt stability under dynamic loads

Prevent component wear and distortion

Extend machine service life by ensuring tight and secure joints

Whether it’s a hydraulic cylinder joint or a structural frame assembly, M16 mild steel washers play a critical role in reducing downtime and enhancing safety.

2. Automotive and Commercial Vehicle Assembly

In the automobile sector, M16 Mild Steel Plain Washers are used extensively in:

Chassis assemblies

Engine components

Axle mountings

Suspension and steering systems

These washers help maintain proper bolt tension and prevent loosening caused by road vibrations and thermal expansion. Their use ensures long-term vehicle integrity, especially in trucks, buses, and off-road vehicles.

3. Infrastructure and Construction Projects

In the construction and civil engineering sectors, M16 washers are integral to:

Steel structure fabrication

Scaffolding systems

Bridge joints and connections

Pre-engineered building frameworks

They distribute loads over wider areas, minimizing surface indentation and preventing pull-through, especially when working with softer materials like wood or aluminum panels.

4. Power Plants and Energy Sector

In thermal, hydro, and renewable energy plants, M16 washers are found in:

Turbine enclosures

Generator mountings

Structural bracing assemblies

Electrical switchgear installations

These washers offer mechanical stability in high-temperature and high-vibration areas, ensuring operational safety and reliability. Their performance is critical for continuous, uninterrupted power supply.

5. Railway and Metro Infrastructure

M16 Mild Steel Plain Washers are used extensively in:

Track fastening systems

Overhead equipment supports

Coach body assemblies

Signal tower installations

Their ability to maintain bolt integrity in high-speed and high-vibration environments makes them an essential part of rail infrastructure.

6. Agricultural Machinery

Tractors, harvesters, and other agricultural implements rely on M16 washers for:

Frame stability

Implement joint locking

Engine and gearbox assembly

They prevent bolt head and nut damage while operating in dusty, rugged, and corrosive conditions, enhancing equipment durability during field operations.

7. Manufacturing and Assembly Lines

Factories with automated production lines use M16 washers in equipment like:

Conveyor belt systems

Robotic arms and pick-and-place units

CNC machines and presses

They enhance the mechanical stability of movable and static joints, especially where repetitive motion and torque stress are common.

8. Marine and Shipbuilding Industry

Although mild steel is typically coated or treated for marine use, M16 washers with proper anti-corrosion finishing are used in:

Dockyard equipment

Boat engine mounts

Deck machinery

Their flat design and load-distribution properties make them suitable for non-submerged parts exposed to salt-laden environments, when adequately protected with coatings.

9. General Fabrication and Industrial Maintenance

M16 washers are found in nearly every fabrication shop or maintenance department. Whether it’s:

Retrofitting equipment

Assembling steel furniture

Fixing HVAC units

Installing heavy-duty shelving

They are essential in ensuring secure, long-lasting bolted connections in both temporary and permanent fixtures.

10. Renewable Energy Equipment

Wind turbines, solar panel structures, and biogas plant frameworks utilize M16 washers to:

Provide extra clamping surface

Withstand cyclical loads from natural elements

Prevent metal fatigue in bolted joints exposed to wind or heat

Mild steel washers, when zinc-coated or treated, offer a cost-effective, durable solution for mounting and maintaining renewable energy systems.

Why Buy M16 Mild Steel Plain Washers in Bulk

- Volume discounts available for bulk orders

- Consistent inventory reduces production delays

- Custom packaging options for OEM and project-based clients

- Fast delivery for recurring orders

- Easier project planning and execution

Businesses can Buy M16 Mild Steel Plain Washers in Bulk to optimize operational efficiency and reduce per-unit costs.

Why Choose the Best M16 Mild Steel Plain Washers Manufacturer

As the Best M16 MS Flat Washers Manufacturer, Nafees Metal Industries offers:

- ISO-certified production lines

- In-house R&D for continuous improvements

- Advanced tooling capabilities

- Short lead times

- Strict adherence to international standards (DIN, ASTM)

We also offer third-party inspection and batch traceability upon request.

Installation Tips

- Inspect the washer for cracks, bends, or corrosion

- Ensure compatibility with M16 bolts

- Clean the surface before installation to avoid uneven load

- Place the washer between bolt head and surface, or between nut and surface, or both

- Tighten to recommended torque values

Using washers on both sides can improve load balance.

Maintenance Guidelines

- Store in dry, cool environments

- Avoid contact with acidic or salty substances

- Inspect periodically for rust or deformation

- Clean with mild detergent and dry immediately

- Replace if there’s loss of shape or structural integrity

Case Study: Enhancing Assembly Line Durability in Heavy Equipment Manufacturing

Client Background

A large-scale heavy equipment manufacturing company based in India approached us with recurring concerns about the durability and alignment of components used in their hydraulic and structural assemblies. They operate across multiple states with high-volume production of excavators, loaders, and bulldozers—where structural integrity under stress and vibration is critical.

Challenge

The client was facing issues with:

Component misalignment during machine operation

Premature loosening of bolts in high-vibration environments

Inconsistent performance in assembly lines due to substandard washers

Significant downtime from frequent maintenance checks

They had been using generic, low-grade washers which could not provide reliable clamping force. These washers would deform or corrode, compromising the torque retention of fasteners. This led to higher replacement costs and unwanted halts in the production process.

Solution

After an in-depth analysis of their operational environment, we recommended transitioning to M16 Mild Steel Plain Washers, engineered to support medium-duty industrial use. These washers were manufactured under strict quality control, ensuring:

Perfect dimensional accuracy

Anti-burr finish for smooth assembly

Mild steel tensile strength suitable for the pressure requirements of the client’s hydraulic systems

We also offered washers with a zinc coating to improve corrosion resistance, as the machines frequently operated in outdoor and high-humidity environments.

Implementation

The washers were introduced across all bolt joints using M16 fasteners. Our technical team worked in tandem with their assembly engineers to map exact stress points where washers needed reinforcement.

Key implementation steps:

We supplied M16 Mild Steel Plain Washers in bulk, ensuring consistent inventory and reducing procurement delays.

We monitored torque consistency post-installation for the first two production cycles.

Our quality assurance department provided regular strength and coating test reports to assure compliance.

The client also received documentation on torque settings, washer reusability recommendations, and corrosion monitoring strategies.

Results Achieved

Within 3 months of integration:

Fastener loosening incidents dropped by 84%, especially in equipment that operated in rugged terrains.

Assembly time improved by 16%, as washers provided better alignment and ease during tightening.

Maintenance frequency decreased, allowing machines to operate for longer hours without component inspection.

Client reported over ₹12 lakhs in cost savings from reduced downtimes and rework.

Positive feedback was received from their distributors and service centers regarding long-term machine reliability.

Why M16 Mild Steel Plain Washers Were Ideal

The selected washers were optimal due to their balance of affordability and performance. With consistent outer diameter and flat surface geometry, they distributed the load evenly and prevented stress concentration on joints. Their smooth, anti-rust finish made them particularly suited for semi-exposed machine parts.

Conclusion

This case study showcases how M16 Mild Steel Plain Washers can play a crucial role in high-demand manufacturing environments. The transition to a reliable washer solution not only enhanced mechanical performance but also improved production efficiency, proving that sometimes the smallest components make the biggest difference.

Related Products or Variants

- M12 Mild Steel Plain Washers

- M20 Mild Steel Plain Washers

- M16 SS202 Washers

- Coated MS Flat Washers (Black Oxide / Zinc)

- Custom size MS Washers on request

Also check our Stainless Steel Flat Washers and SS202 Washers for corrosion-prone environments.

Final Words / Call to Action

In fast-paced industrial environments, choosing the right washer can determine the success and longevity of your assembly. Our M16 Mild Steel Plain Washers offer high strength, dimensional precision, and unbeatable affordability.

Trust Nafees Metal Industries for your next bulk order and experience reliable delivery and outstanding quality. Contact us today to place your order or request a quote.

FAQs – M16 Mild Steel Plain Washers

1. What is the standard size of an M16 Mild Steel Plain Washer?

17mm inner diameter, 30mm outer diameter, 2mm thickness.

2. Can these washers be reused?

Yes, provided they are not deformed or corroded.

3. Are these washers suitable for outdoor use?

Only if they have a protective coating like zinc or black oxide.

4. What is the typical hardness of mild steel washers?

Between 80-100 HV depending on treatment.

5. Do you offer ROHS or REACH certification?

Yes, on request.

6. Can I use them with stainless steel bolts?

Yes, though galvanic corrosion should be considered in moist environments.

7. What’s the lead time for a bulk order?

Usually 5-10 days depending on volume.

8. Are these washers DIN compliant?

Yes, we follow DIN 125 / ISO 7089.

9. Can I customize the thickness or diameter?

Absolutely, custom sizes are available.

10. Is laser marking available?

Yes, for orders above 5000 pieces.

11. What packaging options do you offer?

Boxes, bags, or branded cartons depending on order size.

12. What if I receive damaged washers?

We offer a replacement guarantee for transit damage.

13. What’s the minimum order quantity?

As low as 500 pieces.

14. Can I get a sample before placing a bulk order?

Yes, samples are available upon request.

15. What makes Nafees Metal Industries the best choice?

Our in-house manufacturing, strict QC, and customer-first approach make us the Best M16 MS Flat Washers Manufacturer in India.

Why Choose Nafees Metal Industries?

At Nafees Metal Industries, we believe in delivering more than just washers — we deliver trust, quality, and value. As a leading supplier of M16 Mild Steel Plain Washers, we provide:

✔️ State-of-the-art manufacturing with strict quality control

✔️ Bulk orders with consistent supply

✔️ Customization options for sizes and coatings

✔️ Transparent pricing and fast delivery

✔️ Dedicated support to meet your project timelines

Whether you need a small batch or want to Buy M16 Mild Steel Plain Washers in Bulk, we ensure you receive products that match your exact specifications and industry requirements.

Visit Us

Discover how our washers can improve your assemblies. Visit our fully equipped manufacturing unit at Reay Road, Mumbai, or get in touch with our team for a free quote or customized bulk order. Nafees Metal industries— your trusted partner for high-performance plain washers.

M16 Mild Steel Plain Washers

16 people are viewing this product right now

₹1.68 Original price was: ₹1.68.₹1.40Current price is: ₹1.40. /per piece

Specification:

Material: Mild Steel

Nominal Size (g): M16

Inner Diameter (ID): 17 mm

Outer Diameter (OD): 30 mm

Thickness (t): 3 mm

Minimum order quantity: 5000 pieces

Estimated delivery:13 days

M16 Mild Steel Plain Washers – Precision-Engineered Strength for Every Industrial Application

Introduction

Washers are often the unsung heroes in industrial applications. Their small size belies the massive impact they have in ensuring the integrity, safety, and longevity of fastened components. In heavy-duty or high-vibration settings, washers play an instrumental role by distributing load, minimizing loosening, and protecting surface finishes.

When selecting a washer, material choice is critical. Each material has a unique behavior under pressure, heat, corrosion, and stress. Mild steel stands out as a cost-effective yet high-performance option, making M16 Mild Steel Plain Washers ideal for a wide range of industrial uses.

At Nafees Metal Industries, we specialize in producing precision-grade M16 Mild Steel Plain Washers tailored to meet industrial standards. With state-of-the-art machinery and rigorous quality control, we’re positioned as your trusted supplier.

Whether you’re seeking durability, affordability, or performance, our M16 Mild Steel Plain Washers deliver uncompromised excellence.

What Are M16 Mild Steel Plain Washers?

M16 Mild Steel Plain Washers are circular, flat components with a central hole that fits M16 bolts and fasteners. Their primary function is to distribute load evenly across the surface, preventing bolt pull-through and protecting the assembly’s integrity.

From a technical standpoint, these washers:

- Spread pressure over a larger area

- Provide resistance against vibration loosening

- Protect surfaces from abrasion

M16 Mild Steel Plain Washers Excel In:

1. Load Distribution

One of the most essential mechanical functions of M16 Mild Steel Plain Washers is their ability to distribute load uniformly. When a bolt or screw is tightened, the pressure exerted can create a concentrated force at the point of contact with the material surface. Over time, this can lead to material fatigue, surface deformation, or even cracking in softer materials.

M16 Mild Steel Plain Washers act as an intermediate layer between the fastener and the material. Their wide bearing surface spreads the load across a larger area, significantly reducing the chances of indentation or localized stress. This feature becomes even more important in applications involving wood, plastic, or composite materials, where surface strength is lower than that of metals.

2. Vibration Resistance

Fasteners in dynamic environments are constantly subjected to vibrations and movement. Without proper dampening, these vibrations can loosen the bolts or nuts over time, resulting in failure of the joint. M16 Mild Steel Plain Washers help minimize this risk.

They serve as cushions that absorb minor shocks and vibrations, reducing micro-movements that can loosen fasteners. While they are not a replacement for locking washers in extremely high-vibration scenarios, M16 Mild Steel Plain Washers still offer an essential first line of defense against joint failure caused by repeated motion. This makes them valuable in automotive, machinery, and structural applications where stability is critical.

3. Surface Protection

Direct contact between the fastener and the material surface can lead to wear and surface damage. Over time, metal-on-metal interaction can cause scratches, dents, and in some environments, accelerated corrosion due to frictional wear or exposure to moisture.

M16 Mild Steel Plain Washers serve as a protective buffer. They isolate the fastener from the material, preserving the finish and preventing galvanic corrosion when different types of metals are used in an assembly. This is particularly beneficial in aesthetic applications or in products exposed to weather elements where long-term corrosion resistance is desired.

4. Long-Term Benefits

Using M16 Mild Steel Plain Washers may seem like a small addition, but it leads to significant long-term performance improvements. Assemblies that include washers tend to have fewer issues with fastener loosening, surface degradation, or mechanical wear.

Over extended periods, this translates to reduced maintenance frequency, lower replacement costs, and enhanced operational safety. Whether the washer is used in a static structure or a moving component, its impact on longevity is tangible. It also ensures that periodic re-tightening of fasteners is minimized, saving time and labor in industrial and commercial setups.

5. Material-Specific Properties of Mild Steel

M16 Mild Steel Plain Washers are manufactured from mild steel—a material known for its excellent balance of strength, ductility, and affordability. Mild steel can be easily cut, punched, or pressed into shape, making it ideal for producing large volumes of washers with consistent precision.

Its mechanical properties are well-suited for medium-load applications where toughness and resistance to deformation are more critical than hardness. Moreover, mild steel can be galvanized or plated for corrosion resistance, further extending the washer’s lifespan in harsh or outdoor environments. Its cost-efficiency makes it an ideal choice for industries aiming to maintain quality without inflating production budgets.

Material Details: Why Mild Steel?

Mild steel (commonly referred to as MS) is a low-carbon steel offering a fine balance between strength, flexibility, and cost-efficiency.

Composition of Mild Steel:

- Carbon: 0.05% – 0.25%

- Iron: Balance

This low carbon content enhances ductility and weldability, making mild steel ideal for plain washers.

Comparison with Other Grades:

- SS304: Higher corrosion resistance but costlier

- SS316: Marine-grade corrosion resistance but not needed for general use

- Mild Steel: Best for indoor or non-corrosive environments at a much lower cost

Advantages:

- Excellent machinability

- Superior weldability

- Cost-effective for large-scale production

- High load-bearing capacity

Mild steel is perfectly suited for M16 Mild Steel Plain Washers, providing a durable and budget-friendly solution.

Manufacturing and Technical Specifications

We employ advanced manufacturing techniques, including:

- Precision stamping using high-tonnage power press machines

- CNC machining for dimensional accuracy

- Heat treatment to enhance durability

- Surface coating (zinc, black oxide) upon request

All washers undergo rigorous quality checks for thickness, diameter, and flatness.

Technical Specifications Table:

| Parameter | Specification |

|---|---|

| Inner Diameter | 17 mm |

| Outer Diameter | 30 mm |

| Thickness | 2 mm |

| Finish | Self-finish / Zinc / Black Oxide |

| Material | Mild Steel |

| Shape | Round (Flat) |

Key Features

- Uniform load distribution

- High-precision fit and finish

- Excellent resistance to vibration

- Surface abrasion and corrosion protection (when coated)

- Compatible with various bolt types

- Designed for structural durability

- Suitable for automated assembly systems

- Customizable in terms of thickness and diameter

Applications of M16 Mild Steel Plain Washers

M16 Mild Steel Plain Washers are highly versatile mechanical components used across a broad range of industries and applications. Their primary function is to distribute the load of a threaded fastener and prevent damage to the joint surface, but their importance goes far beyond basic fastening. Here is an in-depth look at where and how these washers are commonly used:

1. Heavy Machinery and Equipment Manufacturing

M16 washers are a staple in the assembly of heavy-duty machines such as bulldozers, cranes, and earthmovers. In such environments, equipment is exposed to extreme mechanical loads, vibrations, and high torque. The washers help:

Maintain bolt stability under dynamic loads

Prevent component wear and distortion

Extend machine service life by ensuring tight and secure joints

Whether it’s a hydraulic cylinder joint or a structural frame assembly, M16 mild steel washers play a critical role in reducing downtime and enhancing safety.

2. Automotive and Commercial Vehicle Assembly

In the automobile sector, M16 Mild Steel Plain Washers are used extensively in:

Chassis assemblies

Engine components

Axle mountings

Suspension and steering systems

These washers help maintain proper bolt tension and prevent loosening caused by road vibrations and thermal expansion. Their use ensures long-term vehicle integrity, especially in trucks, buses, and off-road vehicles.

3. Infrastructure and Construction Projects

In the construction and civil engineering sectors, M16 washers are integral to:

Steel structure fabrication

Scaffolding systems

Bridge joints and connections

Pre-engineered building frameworks

They distribute loads over wider areas, minimizing surface indentation and preventing pull-through, especially when working with softer materials like wood or aluminum panels.

4. Power Plants and Energy Sector

In thermal, hydro, and renewable energy plants, M16 washers are found in:

Turbine enclosures

Generator mountings

Structural bracing assemblies

Electrical switchgear installations

These washers offer mechanical stability in high-temperature and high-vibration areas, ensuring operational safety and reliability. Their performance is critical for continuous, uninterrupted power supply.

5. Railway and Metro Infrastructure

M16 Mild Steel Plain Washers are used extensively in:

Track fastening systems

Overhead equipment supports

Coach body assemblies

Signal tower installations

Their ability to maintain bolt integrity in high-speed and high-vibration environments makes them an essential part of rail infrastructure.

6. Agricultural Machinery

Tractors, harvesters, and other agricultural implements rely on M16 washers for:

Frame stability

Implement joint locking

Engine and gearbox assembly

They prevent bolt head and nut damage while operating in dusty, rugged, and corrosive conditions, enhancing equipment durability during field operations.

7. Manufacturing and Assembly Lines

Factories with automated production lines use M16 washers in equipment like:

Conveyor belt systems

Robotic arms and pick-and-place units

CNC machines and presses

They enhance the mechanical stability of movable and static joints, especially where repetitive motion and torque stress are common.

8. Marine and Shipbuilding Industry

Although mild steel is typically coated or treated for marine use, M16 washers with proper anti-corrosion finishing are used in:

Dockyard equipment

Boat engine mounts

Deck machinery

Their flat design and load-distribution properties make them suitable for non-submerged parts exposed to salt-laden environments, when adequately protected with coatings.

9. General Fabrication and Industrial Maintenance

M16 washers are found in nearly every fabrication shop or maintenance department. Whether it’s:

Retrofitting equipment

Assembling steel furniture

Fixing HVAC units

Installing heavy-duty shelving

They are essential in ensuring secure, long-lasting bolted connections in both temporary and permanent fixtures.

10. Renewable Energy Equipment

Wind turbines, solar panel structures, and biogas plant frameworks utilize M16 washers to:

Provide extra clamping surface

Withstand cyclical loads from natural elements

Prevent metal fatigue in bolted joints exposed to wind or heat

Mild steel washers, when zinc-coated or treated, offer a cost-effective, durable solution for mounting and maintaining renewable energy systems.

Why Buy M16 Mild Steel Plain Washers in Bulk

- Volume discounts available for bulk orders

- Consistent inventory reduces production delays

- Custom packaging options for OEM and project-based clients

- Fast delivery for recurring orders

- Easier project planning and execution

Businesses can Buy M16 Mild Steel Plain Washers in Bulk to optimize operational efficiency and reduce per-unit costs.

Why Choose the Best M16 Mild Steel Plain Washers Manufacturer

As the Best M16 MS Flat Washers Manufacturer, Nafees Metal Industries offers:

- ISO-certified production lines

- In-house R&D for continuous improvements

- Advanced tooling capabilities

- Short lead times

- Strict adherence to international standards (DIN, ASTM)

We also offer third-party inspection and batch traceability upon request.

Installation Tips

- Inspect the washer for cracks, bends, or corrosion

- Ensure compatibility with M16 bolts

- Clean the surface before installation to avoid uneven load

- Place the washer between bolt head and surface, or between nut and surface, or both

- Tighten to recommended torque values

Using washers on both sides can improve load balance.

Maintenance Guidelines

- Store in dry, cool environments

- Avoid contact with acidic or salty substances

- Inspect periodically for rust or deformation

- Clean with mild detergent and dry immediately

- Replace if there’s loss of shape or structural integrity

Case Study: Enhancing Assembly Line Durability in Heavy Equipment Manufacturing

Client Background

A large-scale heavy equipment manufacturing company based in India approached us with recurring concerns about the durability and alignment of components used in their hydraulic and structural assemblies. They operate across multiple states with high-volume production of excavators, loaders, and bulldozers—where structural integrity under stress and vibration is critical.

Challenge

The client was facing issues with:

Component misalignment during machine operation

Premature loosening of bolts in high-vibration environments

Inconsistent performance in assembly lines due to substandard washers

Significant downtime from frequent maintenance checks

They had been using generic, low-grade washers which could not provide reliable clamping force. These washers would deform or corrode, compromising the torque retention of fasteners. This led to higher replacement costs and unwanted halts in the production process.

Solution

After an in-depth analysis of their operational environment, we recommended transitioning to M16 Mild Steel Plain Washers, engineered to support medium-duty industrial use. These washers were manufactured under strict quality control, ensuring:

Perfect dimensional accuracy

Anti-burr finish for smooth assembly

Mild steel tensile strength suitable for the pressure requirements of the client’s hydraulic systems

We also offered washers with a zinc coating to improve corrosion resistance, as the machines frequently operated in outdoor and high-humidity environments.

Implementation

The washers were introduced across all bolt joints using M16 fasteners. Our technical team worked in tandem with their assembly engineers to map exact stress points where washers needed reinforcement.

Key implementation steps:

We supplied M16 Mild Steel Plain Washers in bulk, ensuring consistent inventory and reducing procurement delays.

We monitored torque consistency post-installation for the first two production cycles.

Our quality assurance department provided regular strength and coating test reports to assure compliance.

The client also received documentation on torque settings, washer reusability recommendations, and corrosion monitoring strategies.

Results Achieved

Within 3 months of integration:

Fastener loosening incidents dropped by 84%, especially in equipment that operated in rugged terrains.

Assembly time improved by 16%, as washers provided better alignment and ease during tightening.

Maintenance frequency decreased, allowing machines to operate for longer hours without component inspection.

Client reported over ₹12 lakhs in cost savings from reduced downtimes and rework.

Positive feedback was received from their distributors and service centers regarding long-term machine reliability.

Why M16 Mild Steel Plain Washers Were Ideal

The selected washers were optimal due to their balance of affordability and performance. With consistent outer diameter and flat surface geometry, they distributed the load evenly and prevented stress concentration on joints. Their smooth, anti-rust finish made them particularly suited for semi-exposed machine parts.

Conclusion

This case study showcases how M16 Mild Steel Plain Washers can play a crucial role in high-demand manufacturing environments. The transition to a reliable washer solution not only enhanced mechanical performance but also improved production efficiency, proving that sometimes the smallest components make the biggest difference.

Related Products or Variants

- M12 Mild Steel Plain Washers

- M20 Mild Steel Plain Washers

- M16 SS202 Washers

- Coated MS Flat Washers (Black Oxide / Zinc)

- Custom size MS Washers on request

Also check our Stainless Steel Flat Washers and SS202 Washers for corrosion-prone environments.

Final Words / Call to Action

In fast-paced industrial environments, choosing the right washer can determine the success and longevity of your assembly. Our M16 Mild Steel Plain Washers offer high strength, dimensional precision, and unbeatable affordability.

Trust Nafees Metal Industries for your next bulk order and experience reliable delivery and outstanding quality. Contact us today to place your order or request a quote.

FAQs – M16 Mild Steel Plain Washers

1. What is the standard size of an M16 Mild Steel Plain Washer?

17mm inner diameter, 30mm outer diameter, 2mm thickness.

2. Can these washers be reused?

Yes, provided they are not deformed or corroded.

3. Are these washers suitable for outdoor use?

Only if they have a protective coating like zinc or black oxide.

4. What is the typical hardness of mild steel washers?

Between 80-100 HV depending on treatment.

5. Do you offer ROHS or REACH certification?

Yes, on request.

6. Can I use them with stainless steel bolts?

Yes, though galvanic corrosion should be considered in moist environments.

7. What’s the lead time for a bulk order?

Usually 5-10 days depending on volume.

8. Are these washers DIN compliant?

Yes, we follow DIN 125 / ISO 7089.

9. Can I customize the thickness or diameter?

Absolutely, custom sizes are available.

10. Is laser marking available?

Yes, for orders above 5000 pieces.

11. What packaging options do you offer?

Boxes, bags, or branded cartons depending on order size.

12. What if I receive damaged washers?

We offer a replacement guarantee for transit damage.

13. What’s the minimum order quantity?

As low as 500 pieces.

14. Can I get a sample before placing a bulk order?

Yes, samples are available upon request.

15. What makes Nafees Metal Industries the best choice?

Our in-house manufacturing, strict QC, and customer-first approach make us the Best M16 MS Flat Washers Manufacturer in India.

Why Choose Nafees Metal Industries?

At Nafees Metal Industries, we believe in delivering more than just washers — we deliver trust, quality, and value. As a leading supplier of M16 Mild Steel Plain Washers, we provide:

✔️ State-of-the-art manufacturing with strict quality control

✔️ Bulk orders with consistent supply

✔️ Customization options for sizes and coatings

✔️ Transparent pricing and fast delivery

✔️ Dedicated support to meet your project timelines

Whether you need a small batch or want to Buy M16 Mild Steel Plain Washers in Bulk, we ensure you receive products that match your exact specifications and industry requirements.

Visit Us

Discover how our washers can improve your assemblies. Visit our fully equipped manufacturing unit at Reay Road, Mumbai, or get in touch with our team for a free quote or customized bulk order. Nafees Metal industries— your trusted partner for high-performance plain washers.

Order by 2PM to get delivered next working day! We use 24 hours service with carriers in most cases so that you can get your order delivered on time.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

There is £4.99 charge for delivery under £50 Orders. Additional charges will be imposed by our couriers for delivery to remote area, a surcharge may be levied to cover carriage to these areas.

In stock

- No Defect products

- Plating Charges excluded

- No Returns policy

Categories: Mild Steel Plain Washers, Plain Washers, Washers

Tag: Mild Steel

Got Questions?

Feel free to

Get in touch